roughing end mill cutter diagram

The SSDH series achieves superior chip flow and evacuation through the introduction of chip-release flute form technology and a unique inter-flute helical transition all within a patent pending design. This reduces chatter and vibration.

Illustration Of Face Milling Process Download Scientific Diagram

Side milling curved surface milling and.

. The SS series 3 flute end mill remains the work horse when roughing in ferrous alloy applications. ROUGHING HOG END MILL P36 p38 List 6303X P36 p38 List 6307 P37 p38 Fractional Sizes Fractional Sizes. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

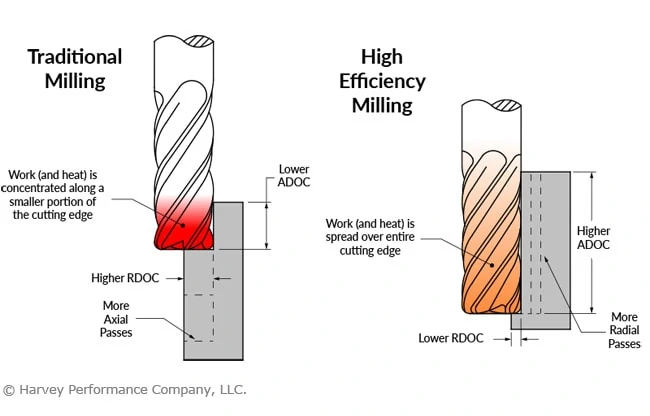

HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material. Slab mills are mostly used in a gang milling processes.

Side loading is dramatically reduced with lower helix angles making it easier to mill thin walls. Design that Virtually Eliminates Flute Packing and Obstruction. Roughing End Mill Cutter Related PostsEnd Mill CutterBall Mill CutterFace Mill CutterHollow Mill CutterSlab Mill CutterThread Mill CutterDovetail CutterFly Cutter.

Normally a 20 reduction in effective horsepower is used. Ball nose cutters or ball end mills lower row in image are similar to slot drills but the end of the cutters are hemispherical. Drill A tool for drilling.

Niagara Cutter Roughing End Mill - REM445 Series Cobalt High Speed Steel Material TiCN Square End 34 in Mill Diameter 4 Flutes 2 in Length of Cut. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. MULTI FLUTE END MILL LONG SINGLE END CENTER CUTTING P44 p45 4 END MILLS VISUAL INDEX List 6230 List 6210 List 6211M List 6211X List 6213 List 6231 TWO FLUTE END MILL SINGLE END P39 p41 List 6231X P39 p41 SpecsSizes SpeedsFeeds FOUR.

A premium rupture resistant substrate is the foundation to. Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill.

Concave Small hollow required on the end face of an Endmill. The roughing end mill has jagged teeth. By using roughing end mills we obtain a rough surface finishing.

Carbide Square End Mills. The cut bits of metal are smaller than usual and therefore easier to clear. Multiple teeth come into contact with the workpiece at the same time.

A standard corner radius protects the tool corner and enhances tool life in aggressive roughing applications. 58 Roughing End Mill. Sign in for your price 9622 each.

Roughing end mills are also famous as rippa cutters. Seco Tools LLC Niagara Cutter N79600. Roughing End Mill 2021-03-26T1328270800.

Basically slab mills are used for machining surfaces which are large as well as broad in shape. ROUGHING END MILLS Roughing cuts are generally for preparing the surface. The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools.

Using Traditional Roughing. Roughers are one of the hardest tools to get right on a tool cutter grinder as the inside of the flute the top face has to be ground where-as a conventional end mill is sharpened by grinding the outside of the cutter. Roughing and Finishing Capabilities.

Roughing end mills are also sometimes known as rippa or ripper cutters. Available in Stub Standard Medium and Reduced Neck. 78 Roughing End Mill.

Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. It is measured from the start of the necked portion to the bottom of the cutting end of the tool. Cutting edges are only on a top.

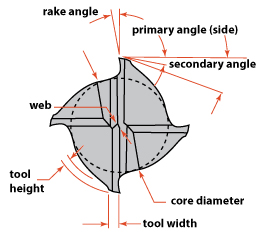

These make the cutting process faster than with a regular end mill. Tertiary 3rd Additional relief clearance provided adjacent to the secondary angle. Roughers have chip-breaker cutting edges the peaks.

They are ideal for machining 3-dimensional contoured shapes in machining centres for example in moulds and dies. The SS series is offered in stub standard. It is possibler to gash a rougher on a tool cutter grinder or even a pedestal grinder with a hand-formed saucer.

Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. End mill A multi-functional tool which has cutting edges on the periphery and an end face. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material.

The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep- pocket milling applications. 12 Roughing End Mill. Multi-flute end mills create better surface finishes due to a lighter chipload - per flute.

While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEM. Slab mills are made from high speed steel. This feature is produced by a dish angle produced on the cutter.

Two flute end mills are center cutting where multi-flute end mills can vary. This type of cutter is used when you have to remove more amount of material from the work piece. These types of milling cutters have the cutting teeth on both sides.

They are more beneficial commercially and are used in various industrial applications. Secondary 2nd angle 14 17 degrees Relief adjacent to the cutting edge. Roughing End Mill - Precision Cutting Tools CNC Milling Tools Supplier.

This spreads wear evenly across the cutting edge dissipates heat and reduces. Roughing End Mill Cutters Shop our selection of roughing cutters for use with any End Mill Notcher that requires a 125 shank. Up to 16 cash back Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

Cutting image by tool bit Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone.

Basic End Mills Technical Information Msc Industrial Supply Co

The Secret Mechanics Of High Feed End Mills In The Loupe

Basic End Mills Technical Information Msc Industrial Supply Co

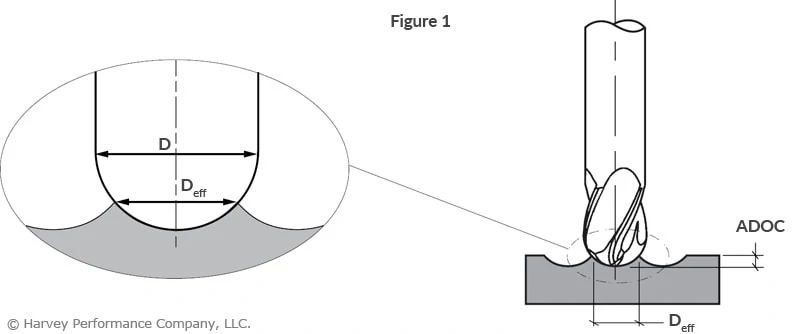

Ball Nose Milling Strategy Guide In The Loupe

Geometry Of Linear And Circular End Milling Process Download Scientific Diagram

Mitsubishi Inserted Cutter Cutter I Cutter Number Bap300r 1608wl16 Download Scientific Diagram

Milling Cutters Types Uses And Selection Principles Machinemfg

Endmill Design Basics Mastercut Tool Corp

End Milling And Peripheral Milling Download Scientific Diagram

Carbide Tipped Milling Cutters Technical Information Hannibal Carbide Tool Hannibal Carbide Tool Inc

Roughing End Mill Kyocera Unimerco

End Mill An Overview Sciencedirect Topics

Schematic Diagram Of The Side Milling Process Download Scientific Diagram

8 Ways You Re Killing Your End Mill In The Loupe

5 Cutter Workpiece Engagement Geometry Extraction For Ball End Mill Download Scientific Diagram

Two Flute End Mill Cutter Geometry Front View Download Scientific Diagram